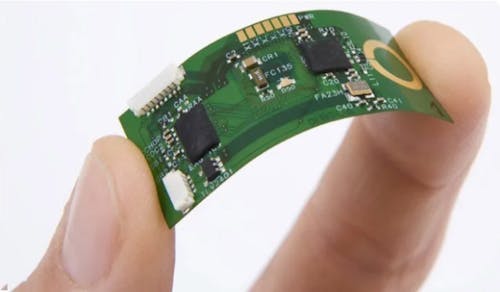

Programming and test fixtures are vital tools to ensure the quality of electronic products. These tools enable test products easily, quick and repetitive, and even make automated test. A good Test fixture improves testing efficiency and accuracy.

These devices hold electronic products while diagnostic, programming or validation tests are performed, are used to connect the product to test and measurement instruments, and are designed specifically for each product and production lines.

Depending on the case, there are different test fixtures. Some of the most common are the following:

ICT Test Fixtures: These fixtures are used to test electronic components and product functions early in manufacturing. ICT test fixtures are used when you test the products to identify assembly and manufacturing problems and reduce production time.

Programming Test Fixtures: These fixtures are used to program product firmware and software at the manufacturing stage or in the field. Programming test fixtures are essential to ensure that the firmware and software are programmed correctly and that the product functions perfectly.

Functional Test Fixtures: These fixtures are used to perform diagnostic and available tests on the complete product. Functional test fixtures are essential to ensure the product functions correctly and meets customer specifications.

Programming and test fixtures are essential for manufacturing high-quality electronic products and reducing production times. By using them, manufacturers can increase efficiency and accuracy by automating testing processes. In addition, they can reduce costs since they detect problems early in mass production.