In modern electronics manufacturing, efficiency and automation are key to staying competitive. The SMEMA (Surface Mount Equipment Manufacturers Association) standard is crucial in automating surface mount technology (SMT) assembly lines by enabling seamless communication between different machines. This article is aimed at engineers who want to deepen their understanding of the SMEMA standard and how it optimizes testing processes, specifically in functional circuit testing (FCT).

What is SMEMA?

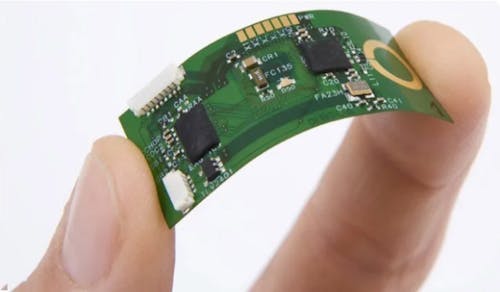

SMEMA stands for Surface Mount Equipment Manufacturers Association. This standard defines the wiring interface used for communication between SMT production equipment—such as stencil printers and pick-and-place machines—on an electronics production line. It allows machines, including intermediate units like conveyors, to communicate whether they are busy or ready to receive a printed circuit board (PCB).

Benefits of SMEMA in SMT Automation

- Standardized communication: SMEMA provides a common language for SMT equipment to communicate, ensuring smooth interoperability.

- Improved automation: By allowing machines to indicate their status to one another, SMEMA enables automated PCB transfers between workstations.

- Increased efficiency: SMEMA-driven automation reduces the need for manual intervention, resulting in faster production cycles and higher overall efficiency.

- Cost reduction: By optimizing workflow and minimizing errors, SMEMA helps lower operational costs in electronics manufacturing facilities.

SMEMA Integration in FCT Systems

FCT (Functional Circuit Testing) is a vital part of the electronics manufacturing process, ensuring that PCBs perform according to design specifications. Integrating SMEMA with FCT systems provides several advantages:

- Automated PCB transfer: SMEMA enables automated transfer of PCBs from the assembly line to the FCT station, reducing manual handling and the risk of damage.

- Optimized scheduling: By communicating with other equipment, the FCT system can synchronize operations to perform tests at the right time and in the correct sequence.

- Real-time data collection: SMEMA facilitates real-time data exchange from the FCT system, delivering valuable insights into product performance and allowing for early detection of potential issues.

- Enhanced quality control: By automating testing processes and providing accurate data, SMEMA contributes to improved quality control and lowers the risk of defective products reaching the market.

Implementing SMEMA in an FCT Environment

Implementing SMEMA in an FCT test environment involves several steps:

- Equipment compatibility: Ensure all equipment involved—including conveyors, assembly machines, and FCT systems—is SMEMA-compatible.

- Wiring connections: Establish proper wiring connections between the equipment according to SMEMA specifications. The plugs and cables are multi-material connectors and receptacles with 14 wire positions, although typically only six wires are used for data. Pin 8 is generally used for shielding.

- Software configuration: Configure the FCT system software to communicate via SMEMA, enabling data exchange and synchronized operations.

- Testing and validation: Perform thorough testing to ensure the SMEMA integration works as expected and all machines communicate correctly.

SMEMA Alternatives: The Hermes Standard

While SMEMA has been widely adopted in SMT automation, it has limitations in data transfer speed and capability. The Hermes Standard provides faster, network-based communication between individual machines—something SMEMA was not originally designed to support. Unlike SMEMA's simple digital signals, the Hermes Standard enables complex data exchange between machines, including product information, transport width, and speed.

SMEMA remains a valuable standard for SMT assembly line automation, especially in FCT environments. By enabling seamless machine-to-machine communication, SMEMA helps optimize testing processes, enhance quality control, and reduce operational costs. As the electronics industry continues to evolve, it's essential for engineers to stay up to date with the latest automation advancements and explore the potential of emerging standards like the Hermes Standard.